DSO 150 : Accuracy part 2, what is happening, how to fix it

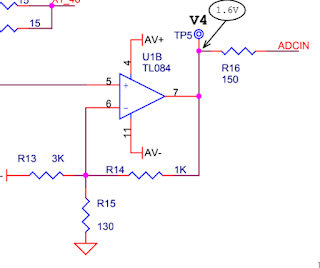

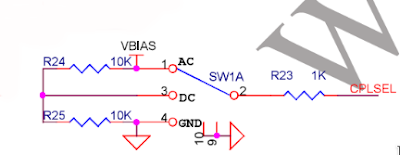

The root cause is the TL084. It is part of several stages in the input chain. It is powered by +-5V and if we look at the datasheet, the output voltage is capped depending on the power supply : With +-5v, the TL084 can actually only output about +-3V according to that spec The real value is much worse, it is actually VCC-4v to be safe (!) So only +-1 swing ! Raising the power supply is not an option, that would not be compatible with unmodified hardware Now let's compute the max value at every point of the input chain MAX @ G3 Max @ G2 Max @ G1B Max IN Max ADC G4 G3 G2 G1A G1G1B Friendly name Actual MAX IN SAT VALUE SAT ADC TL084 SAT V/DIV 1.50 8.00 0.1875 1.00 0.1875 2.00 0.09375 0.91 1.00 0.103125 20mv 20 2 1.50 8.00 0.1875 0.50 0.375 2.00 0.1875 0.91 1.00 0.20625 40mv 40 2 1.50 8.00 0.1875 0.25 0.75 2.00 0.375 0.91 1.00 0.4125 80mv 80 Max V/Div 2 1.50 8.00 0.1875 0.10 1.875 2.00 0.9375 0.91 1.00 1.03125 200mv 200 2 1.50 8.00 0.1875 0.05 3....