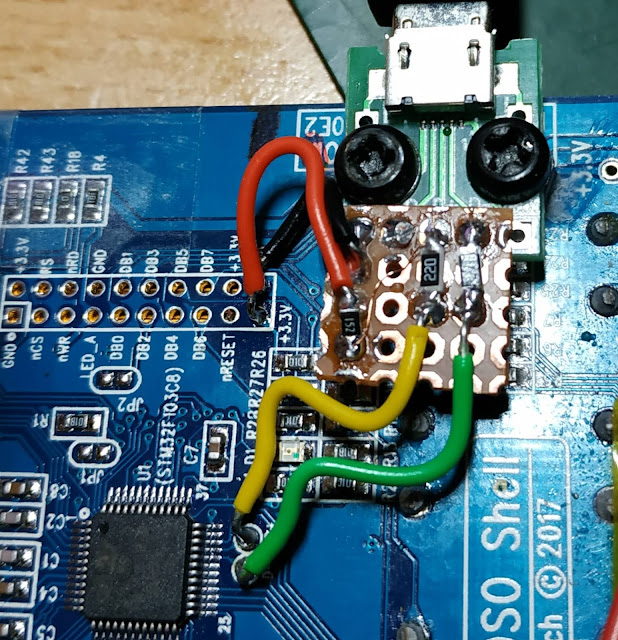

DSO Shell - Rewired rotary encoder + buttons

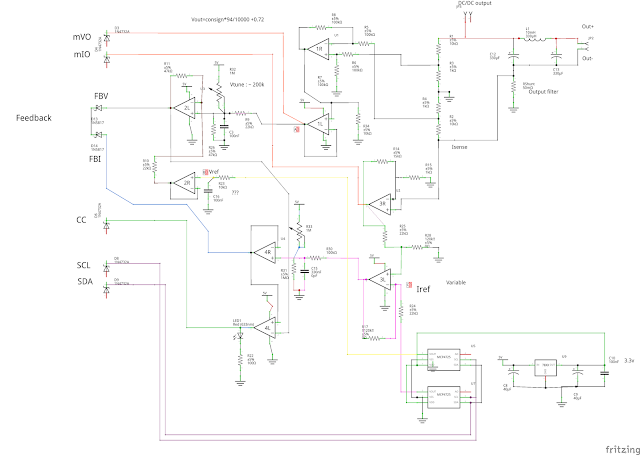

So, as seen previously, the screen is conflicting with the rotary encoder making it very inaccurate and unresponsive. We have freed the RX/TX pins , so we can use them as left/right for the rotary encoder While we are at it, let's add some hardware debouncing to reduce the noise on the interrupt lines of left/right. Again, it does not conflict with the screen any longer, so we can add caps to the lines. I cut the 1 & 2pins below the rotary encoder (the 2 left side on the pic), that disconnects PB0 & PB1. The regular buttons are now managed by a FreeRTOS task that lazily poll them and do software debouncing. Since we are using RX/TX pins, we have the rotary encoder connected to port A. No need to block the EXT irq when updating the screen (port B) => no missed transitions. The interrupt is pretty fast, just a lockup table search. The buttons are a two layers software debouncer, so no interrupt there either. First an integrator debouncer to filte