Cheap HandHeld : Reusing the LCD

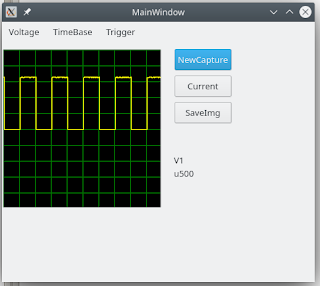

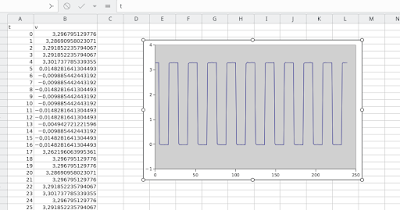

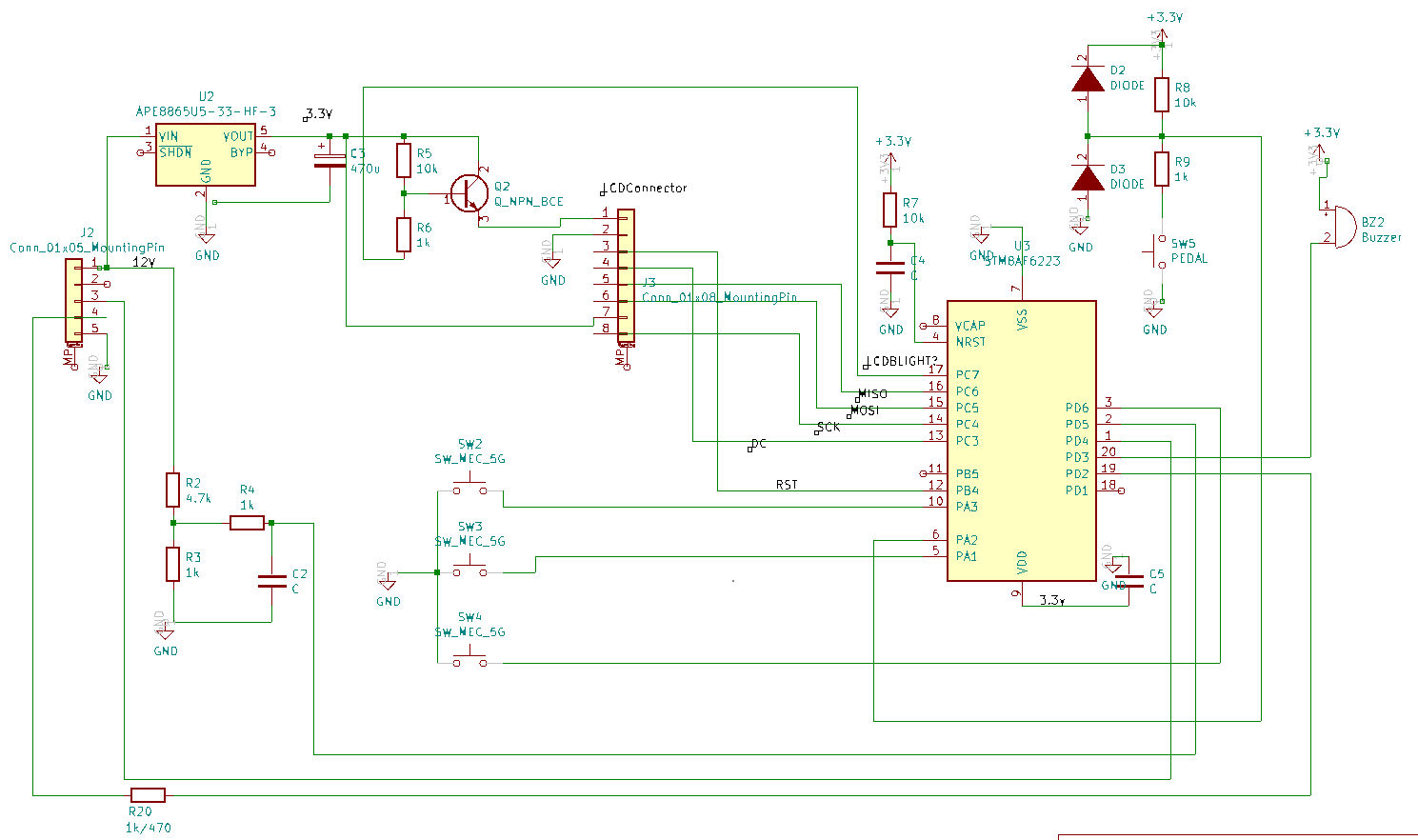

Edit : Check the next post, it is actually a 16 bits standard 8080 bus I though i could re-use the 320x240 IPS LCD of those cheap units to do other things, there are a lot of test points to solder wires on them and convert them to something easier to use. The connector is 24 pins and a lot of them have fast data signals or VCD/GND. No slow signals such as RD/WR/CS/... I opened the LCD to see if i could identify the chip driving them : couldnt find one So either it's a very very tiny one (unlikely) OR the controller is inside the chip and the LCD is just a LCD (for cost reason) That's a bummer.