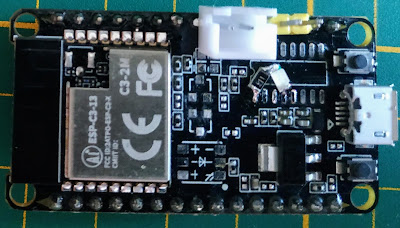

esp32C3: Using embedded jtag/usb to debug

This is a follow up to the ESP32C3 jtag setup The idea here is to detail the missing pieces in the documentation to use the embedded jtag/usb converter. I'll be a bit heavy handed in removing stuff, it may not be 100% necessary. Your mileage may vary. Jtag setup The esp32c3 has regular jtag pins connected to GPIO 4/5/6/7 It also has a internal usb jtag+CDC/ACM connected to pins GPIO 18 & 19. By default it's using the usb/jtag one EFuse There is a efuse to automatically switch from internal jtag/usb to external jtag depending on the GPIO10 state at boot up It does not work , there is an bug entry . If you enable that bit (JTAG_SEL) it will use external jtag, period, never internal usb/jtag. Ifever you modified it, like i did, you can recover usb/jtag by setting the disable pad jtag efuse, and it will be locked on usb/jtag forever. In short, use USB/jtag only and dont play with the efuses. Leds everywhere On the devkit or similar boards from alibaba the j...